Rapid Liquid Printing Between Magic and Material𝗹

Image: © ainewsinsider Edited by Ulrich Buckenlei | Taken at Vivatech 2025, own photo

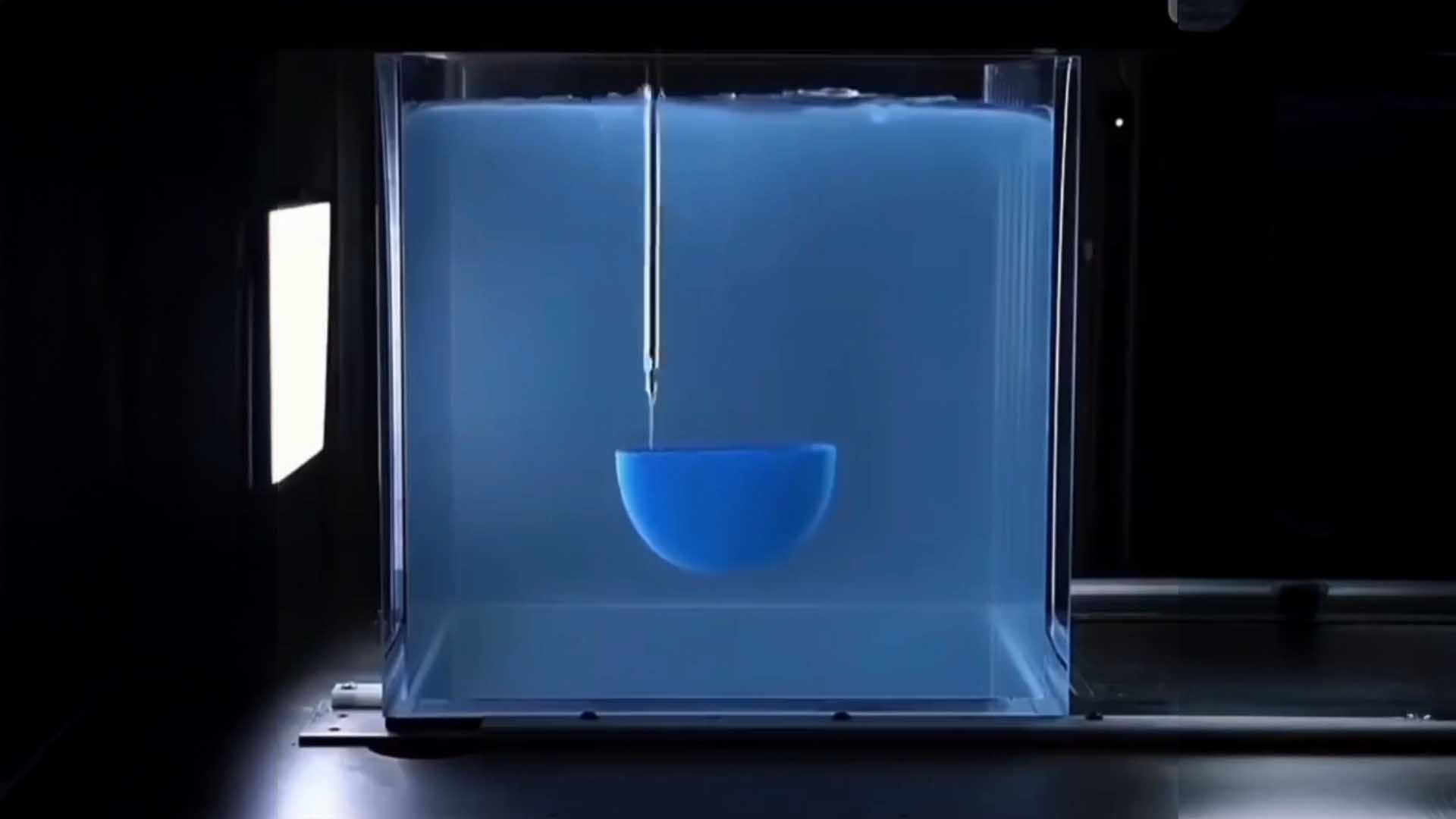

Printed in Space – The Principle of Rapid Liquid Printing

What is created here is not conventional 3D printing. Rapid Liquid Printing (RLP) is based on a technique where the printing material is not layered but drawn freely into a gel structure. A robotic arm moves through the substance – creating a three-dimensional form within seconds.

- Printing without gravity: The gel holds the material precisely in place.

- No layering: Free drawing instead of rigid layers.

- Faster, more flexible, more aesthetic: Ideal for fashion, design, research.

Direct printing into a gel medium – RLP in action

Image: © ainewsinsider Edited by Ulrich Buckenlei | Vivatech 2025 – Showcase from Fashion Tech

The process opens new pathways for designers: forms emerge freely in space, uninhibited by gravity – and ready to use.

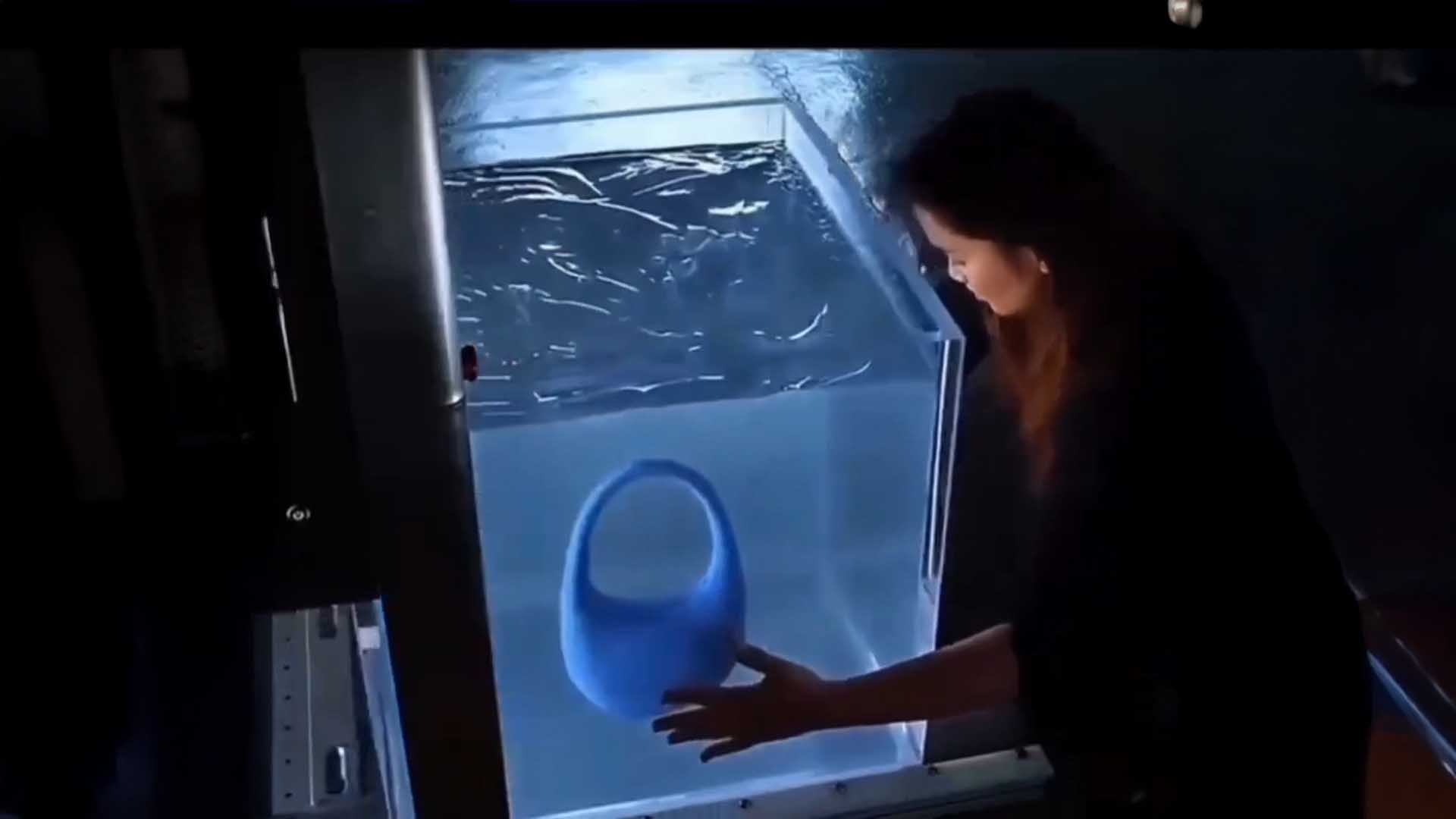

From Form to Function

The RLP process enables flowing, organic forms that were previously almost impossible. In the example shown, a flexible silicone bag is printed – including functional details, all in a single step.

- Continuous form generation: No layer breaks, no separation between structure and design.

- Smart control: Movement, material flow, and pressure regulated in real time.

- Sustainable & efficient: No material waste, no support structures needed.

A product emerges in space – without post-processing

Image: © ainewsinsider Edited by Ulrich Buckenlei | Real-time print at Vivatech 2025

The gel casing produces soft edges, clean details, and a nearly meditative aesthetic. The future of shaping is liquid.

Magic in Suspension – Aesthetics Meets Technology

RLP is not just a technical innovation – it’s also a visual spectacle. As the robotic arm moves, hypnotic structures arise that oscillate between art and technology.

- Performance printing: The manufacturing process becomes a show.

- Material aesthetics: The silicone resembles glass, light refracts along each line.

- New design language: Between organic and algorithmically generated.

Material meets motion – design directly from the gel

Image: © ainewsinsider Edited by Ulrich Buckenlei | Real-time printing with soft actuator system

A seamless transition between construction and result. The gel adds a sense of weightless elegance to the process.

Industry, Fashion, Medicine – Changing Fields of Application

RLP isn’t just for showcases – practical applications are emerging in industry, prototyping, and the medical field. From personalized orthoses to rapid design prototypes.

- Fashion & design: Custom textiles and accessories on demand.

- Industry & research: Components, forms, functional objects in a single pass.

- MedTech & bioprinting: Experiments with gel as a medium for living cells.

Industry, fashion, medicine – changing applications. Silicone object from gel – ready to use

Image: © Ulrich Buckenlei | Product removal after printing process

The process shows how design and technology are increasingly merging – the medium becomes an active partner in creation.

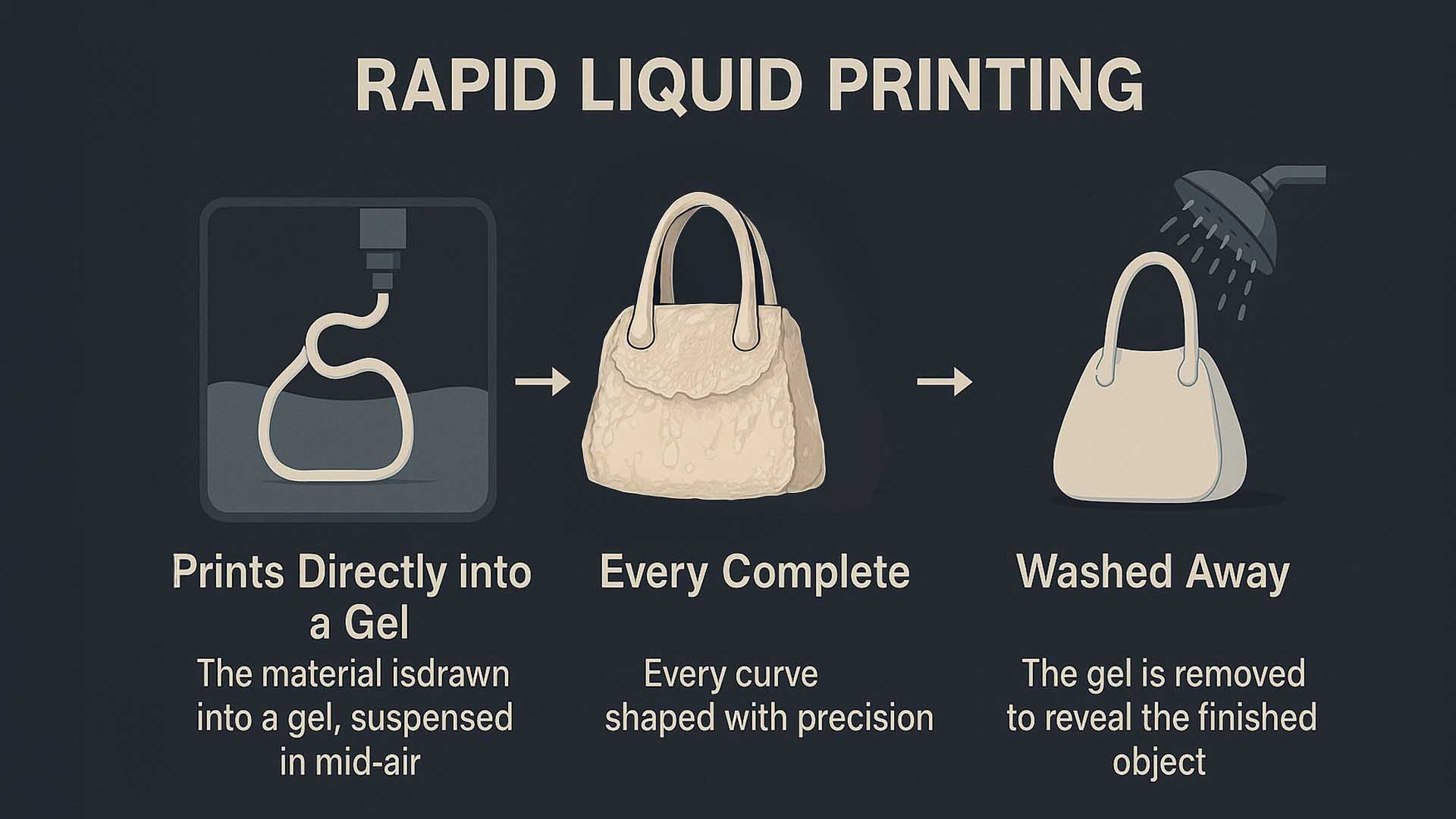

Visual Summary – How Does Rapid Liquid Printing Work?

Infographic: Process and benefits at a glance

Graphic: © Ulrich Buckenlei XR Stager NewsRoom | Depiction of the process workflow

The gel functions as a stabilizer – the viscosity allows three-dimensional drawing without the form sinking or slipping.

Video: Rapid Liquid Printing Live at Vivatech

This video shows the full process – from the beginning of the movement to the release of the finished product.

Video: The object is created live in suspension

Video: © ainewsinsider Edited by Ulrich Buckenlei | Recording from Vivatech 2025

The Future at Your Fingertips – Get a Consultation

The Visoric expert team supports you in the conception, planning, and implementation of innovative printing processes, immersive showcases, and visionary design workflows.

- Industry & prototyping: Customized applications in gel, printing, simulation

- UX & presentation: Making digital content physically tangible

- Events & communication: Visual highlights for trade fairs and brand appearances

Get in touch now – let’s bring your vision into shape together!

Contact Us:

Email: info@xrstager.com

Phone: +49 89 21552678

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobil +49 152 53532871

Mail: ulrich.buckenlei@xrstager.com

Nataliya Daniltseva (Projekt Manager)

Mobil + 49 176 72805705

Mail: nataliya.daniltseva@xrstager.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich