Immersive Simulations with 360° Freedom of Movement

Visualization: © Ulrich Buckenlei | Symbolic image for immersive simulation development using VR sphere systems

Engineering Meets Immersion

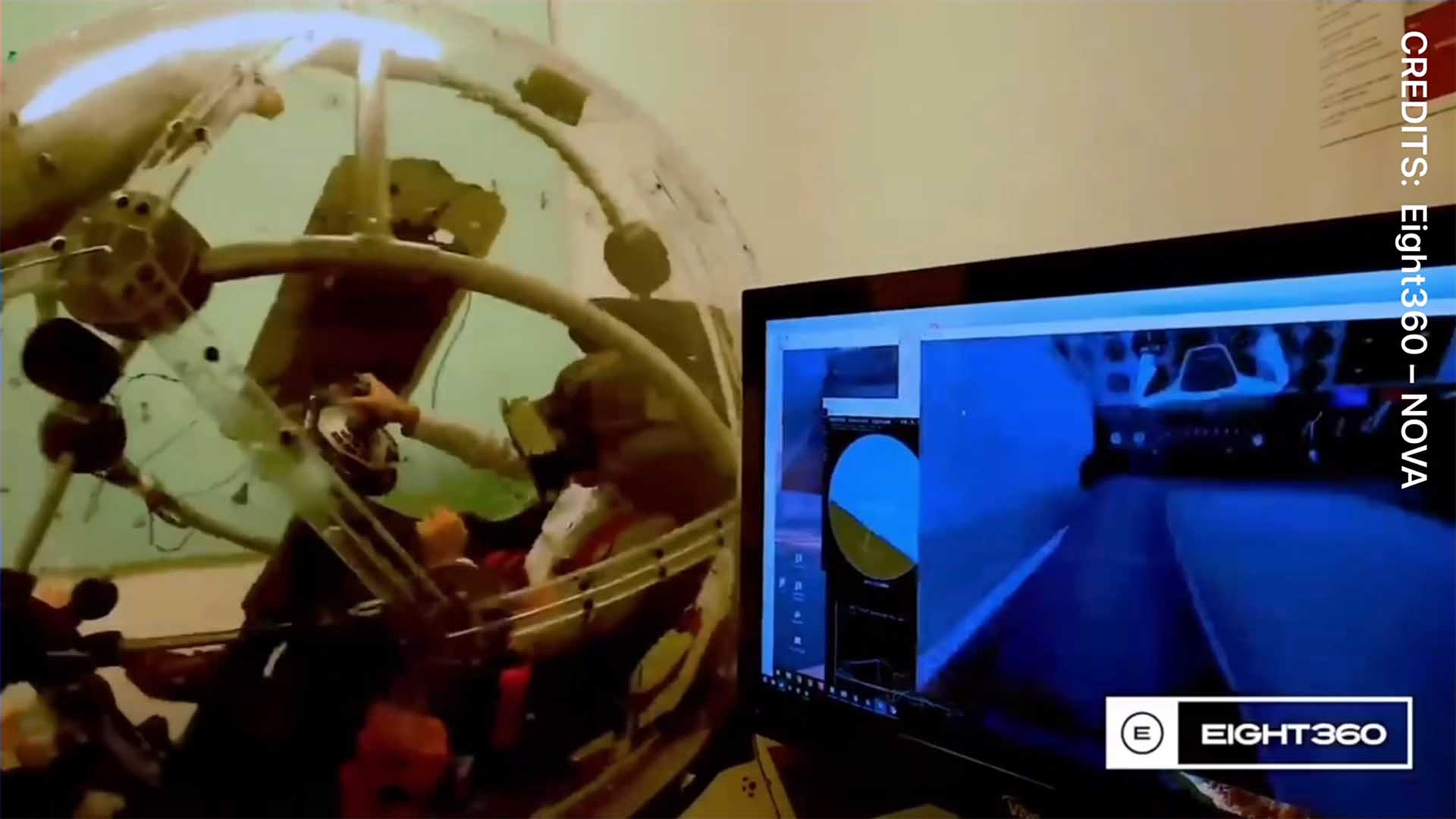

At first glance, the transparent sphere looks futuristic – but its impact goes far beyond that. Inside, a precise rotor platform rotates freely along all three axes. The movements are not only visible but also physically perceptible. This makes the sphere an immersive engineering tool.

- 360° Motion Experience: Freely rotatable in all directions for realistic motion sequences.

- Modular and Transparent: Open structure for technical insights and flexible use.

- Real Feedback: Mechanical behavior directly experienced in real time.

Insight into the mechanical construction of the simulation sphere

Image source: Eight360 – NOVA

The transparent outer shell not only allows observation but also enables targeted integration into development labs and training centers. The interaction between human, machine, and digital model becomes the central focus here.

Digital Twin – The Virtual Copy in Real Time

The combination of real movement and virtual representation opens up completely new simulation approaches. A digital twin mirrors every movement of the sphere live. Reactions, material behavior, and loads are digitally analyzed and documented.

- Live Mirroring: Movement, position, and feedback captured in digital real time.

- Performance Analysis: Optimization possibilities through AI-supported evaluation.

- Digital Transformation: Merging engineering and simulation.

Real-time rendering and motion feedback: Aircraft simulation becomes a realistic training experience

Image source: Eight360 – NOVA

With every simulated moment, the models improve – through machine learning, system behavior and control processes are intelligently advanced.

Mixed Reality – Design Meets Reality

Overlaying 3D models in real time allows engineers to visualize design changes directly on the physical object. What was once hidden in CAD software is now visible, tangible – and intuitively understandable.

- Visual Engineering: Design changes in real time as a mixed reality layer.

- Collaboration & Communication: Teams see what has been changed – instantly.

- Innovation Leap: From static model to immersive interaction.

Submarine simulation with immersive real-time overlay

Visualization: Ulrich Buckenlei | VISORIC GmbH

The physical setup remains the same, but the virtual model changes dynamically – a powerful lever for iterative development.

Enhanced Sensor Technology – Capturing the Invisible

Beyond the visible movements, it is especially the invisible reactions that are measurable inside the sphere. Sensors detect the slightest muscle responses, movement resistance, and changes in material.

- Micro-Sensors: Precise analysis under load.

- Reaction Detection: Recording of individual response patterns.

- Intelligent Evaluation: Optimization through data-driven feedback.

Simulation data in real time: Development and validation of new designs directly on the model

Image source: Eight360 – NOVA

Sensor data generates a precise feedback system – the ideal foundation for adaptive learning and testing environments.

Infographic: Immersive Sphere Simulation Explained

Infographic of the simulation sphere with a focus on digital enhancements

Created by Ulrich Buckenlei | VISORIC GmbH

The infographic illustrates the central role of 360° movement, digital twins, mixed reality, and sensor fusion. It demonstrates how the technology can be applied across disciplines.

Video Insight: The Simulation Sphere in Action

VR simulation with submarine overlay and full freedom of movement

Footage: Eight360 – NOVA | Enhancement: VISORIC GmbH

Talk to the VISORIC Expert Team

Would you like to integrate immersive simulations into your product development, training, or customer presentations? Our team will advise you on technical possibilities, visualization concepts, and feasible scenarios. With a focus on engineering, XR, and AI, we develop tailored solutions for demanding projects.

- Consulting & Concept Development: We think interactively and immersively from the start.

- 3D & Real-Time Technology: Customized XR experiences in real-time environments.

- Training & Showcases: We bring innovation to life.

Contact us and shape the next chapter of immersive development with us.

Contact Us:

Email: info@xrstager.com

Phone: +49 89 21552678

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobil +49 152 53532871

Mail: ulrich.buckenlei@xrstager.com

Nataliya Daniltseva (Projekt Manager)

Mobil + 49 176 72805705

Mail: nataliya.daniltseva@xrstager.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich